Research

Making full use of cutting-edge technology, we will maximize the potential of nanomaterials and create new engineering materials!

Although nanocarbon materials such as graphene and carbon nanotubes have excellent properties, actual products using these attractive nanomaterials are limited. In addition to their high material costs, these nanomaterials forms agglomeration due to Van der Waals force, and it is extremely difficult to disperse them in various materials.

In our laboratory, we have succeeded in production of nanomaterials that show high solubility in liquid. We are taking the challenge of mass-production of high-quality soluble nanosheets and creating high-performance nanocomposites. We are developing high-strength polymeric material, thermal conductive materials, transparent conductive films and functional; inks using soluble nanosheets.

1.Mass production of high quality nanosheets

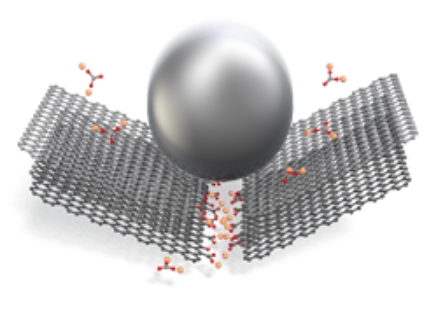

Natural graphite can be exfoliated to few-layer graphene by liquid phase exfoliation (LPE). However, because of low exfoliation efficiency, the graphene yield by LPE is less than 1% per 1 hour of sonication. We have found that mechanochemical reaction occurs during ball milling of graphite, and some chemical absorbed at an activated edge of graphite. This functionalization enables ultra-high exfoliation in liquid. Graphene yield reached more than 50% only 5 min of sonication. Mass production of soluble nanosheets at low energy and low cost have been developed by optimizing this mechanochemical process. Currently, we are trying to produce large nanosheets with a diameter more than 1 mm.

Mechanochemical reaction of graphite with salts during ball milling

Mechanochemical reaction of graphite with salts during ball milling

Exfoliation of graphite in liquid

Exfoliation of graphite in liquid

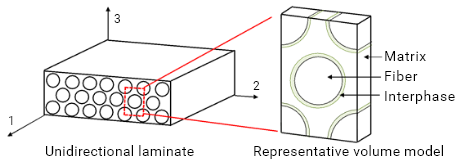

2.Strength improvement of fiber reinforced plastics by introducing reinforced interphase

Due to its high strength and light weight, fiber reinforced plastics (FRP) are adopted in the aerospace and automobile fields. As shown in the figure below, FRP is a material composed of plastics and reinforced fiber with a dimeter of about 10mm. There is thin layer of 100 to 500 nm between fiber and plastics, and it is called interphase. The mechanical properties of this interphase is no yet well understood. We are trying to improve the strength of FRP by reinforcing interphase using graphene.

Fiber reinforced plastics including nano size interphase

Fiber reinforced plastics including nano size interphase

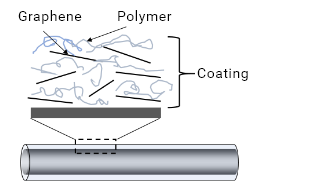

Graphene coating on fiber

Graphene coating on fiber

3.Development of next-generation high strength sheet

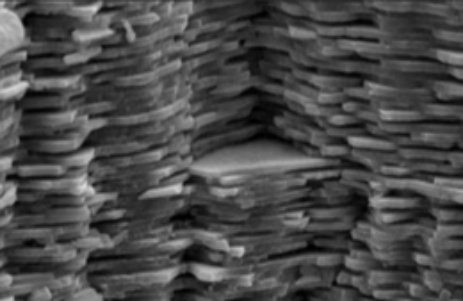

The nacre of a shell has a layered structure in which plates of calcium carbonate are bonded with a polymer. Despite using calcium carbonate, a brittle and weak material, nacre shows high toughness. It is reported that high toughness of nacre ascribes to layered structure, where cracka are trapped and difficult to propagate. Learning from nacre, we are trying to make high strength sheets using graphene. Control of graphene thickness and diameter is important factor for producing high strength layered materials. We will produce next generation sheet that surpass existing high-performance materials such as FRPs.

Cross section image of nacre.

Cross section image of nacre.Calcium carbonate plates are bonded by polymer.